rpm DEFENCE

Solutions specifically for protection wear and equipment for military applications

For over 25 years, we have stood for precise production and smooth processes for prototypes and series. Our experienced engineering, project management and production team ensures fast response time and clear communication.

What can you expect?

- Over 12 in-house production technologies

- Application-specific processes – 3D printing, casting technologies and injection moulding

- Prototypes and small series according series quality

- Smooth transition from part 1 to series

You can rely on certified quality:

DIN ISO 9001:2015 and TISAX Level 3 speak for our standards. Our recognised delivery reliability makes the difference.

Convincing Performance

Customised

Equipment

Effective

Weight Reduction

Design

Expertise

Variety of

Materials

Cost

Efficiency

Solution-orientated through the use of 3D printing technology

You benefit from our expertise in series production using additive manufacturing processes. We provide competent and solution-oriented advice right from development and design phase to ensure smooth implementation. This means a low-risk launch with maximum safety and quality – both for prototypes and your series.

Complete package for perfect results

Our all-round carefree package also includes post-processing such as chemical smoothing, colouring, painting or assembly work. On request, we can pack and dispatch ready for sale to you or your customers.

Maximum variety of materials and shapes

The rpm design expertise combined with innovative additive processes enable the realisation of the most complex geometries. In combination with the right materials, we realise properties that cannot be achieved with conventional manufacturing processes.

Cost-effective even for series

Our high-performance printers enable attractive pricing for series production; even classic injection moulded components can be additively manufactured economically. The costs for moulds are completely eliminated.

Short delivery times

An experienced rpm production team and in-house engineering guarantee the shortest possible realisation time for your products.

Additive Series Production

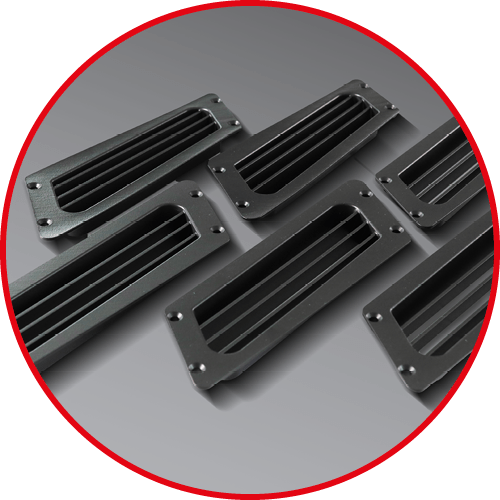

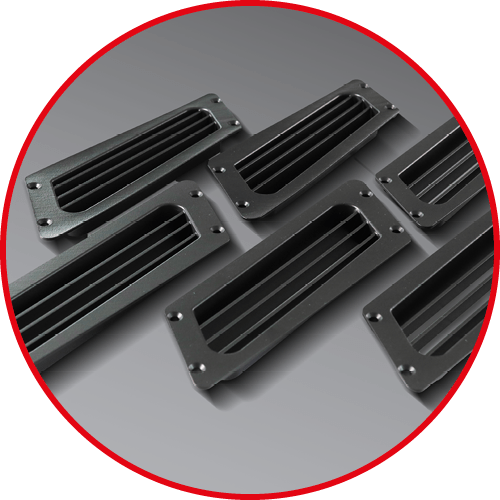

SLS (Selective Laser Sintering)

Series production using thermoplastic materials for robust components with different fields of application

- Wide range of materials (>10 materials) allows you to select the optimum material for your component

- Expert for special materials that are not processed by other suppliers

- In-house workflow for series production

Additive Series Production

DLS (Digital Light Synthesis)

DLS (Digital Light Processing)

Series production using thermoset materials for precise components and soft-elastic ballistic protection

- Printable 2K polyurethanes with various degrees of hardness

- Printable 2K epoxies for increased temperature and flame retardancy

- Printable 1K acrylates for a wide range of applications

- IMDS-listed materials

- Surfaces close to series parts

Competent Consulting, Solution-oriented

Our promise

Our primary goal is to meet your individual requirements with an exceptional level of consulting and solution expertise. By developing tailor-made solutions and using innovative additive manufacturing processes, we implement demanding projects both efficiently and economically. In doing so, we ensure consistently high part quality in additive series production – a claim that we have already successfully proven with thousands of components. You can rely on our experience, precision and innovative strength to manufacture your products.

Dr Jörg Gerken, CEO

rpm rapid product manufacturing GmbH

Customer Feedback

„We are extremely satisfied with the young, dynamic team at rpm. Communication between the engineers, the sales department and us runs smoothly,

and most importantly: they understand us! Problems are approached on equal terms and solutions that work for both sides are found together. We really enjoy working with rpm.“

Tim Pausch,

CEO Send Nods Nightvision

Other production processes

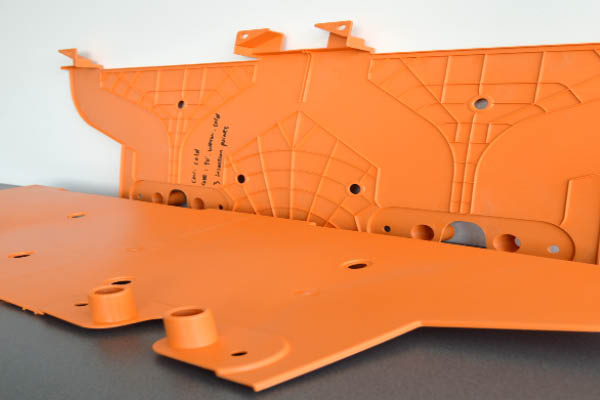

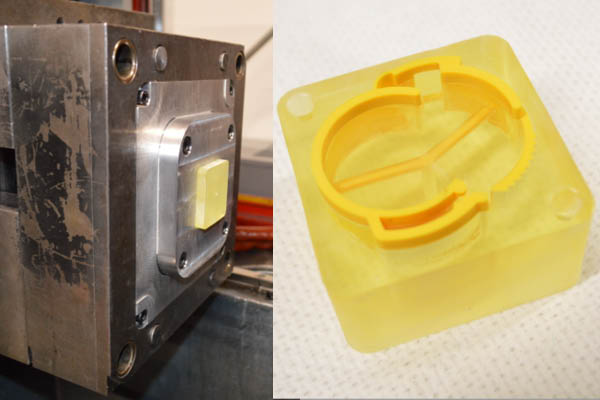

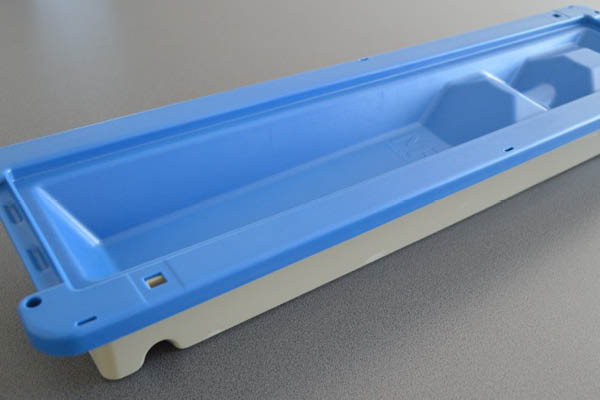

Injection moulding

One-Shot-Molds

Casting

PA casting

PU casting

RIM

Machining

Other production processes

Injection moulding

One-Shot-Molds

Casting

PA casting

PU casting

RIM

Machining

ARE YOU INTERESTED IN WORKING WITH US?

Leave your contact details and our team will get back to you shortly. (We’re not called Rapid Product Manufacturing for nothing!)

TISAX Level 3

Data security and confidentiality

ISO 9001:2015

Quality management system